THE FIRST CHOICE IN CHEMICAL DOSING PROCESS

YANGTECH

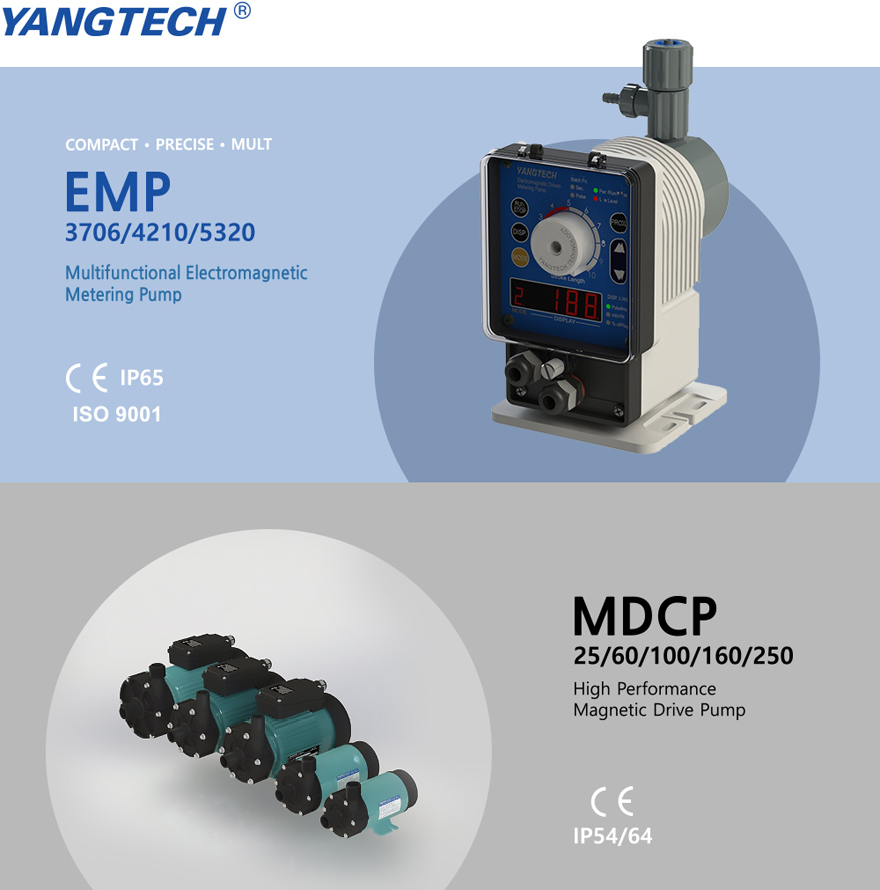

EMP-Series electromagnetic metering pumps feature microprocessor control technology.

They are compact, precise and multifunctional and suitable for precise liquid chemical closing process.

APPLICATIONS

Environmental protection engineering. Cooling tower. Boiler, Swimming pool.

Chemical industry. Food processing and Disinfection,etc.

FEATURES

- Multi-functional LED displays various information, Such as pulse rate / pulse rate percentage / flow rate / time, etc.

- 100V-240V wide range of source power voltage makes more convenient installation.

- Equipped with liquid level sensor contacts. When a level switch is applied, the pump stops automatically when reach the lowest level.

- The electro-magnetic driver equipped with an temperature protector, which secure from high temperature damage.

- External analog signal (4~20mA or 0~10V) control function (optional).

- External digital signal (PLC/counter pulse signal) control function (optional).

- Batch function for both pulse and time count-down (optional).

- Time control on/off function (optional).

- Power supply contact (5V, <500mA) for external sensor/relay (optional).

- Various contacts for external control switches, low level and batch finish alarm (optional).

| A = Series Code | (Pump Series Code) |

| B = Diaphragm Diameter | (37=ø37mm, 42=ø42mm, 53=ø53mm) |

| C = Flow Rate Code | (06=60ml/min, 10=100ml/min, 20=200ml/min) |

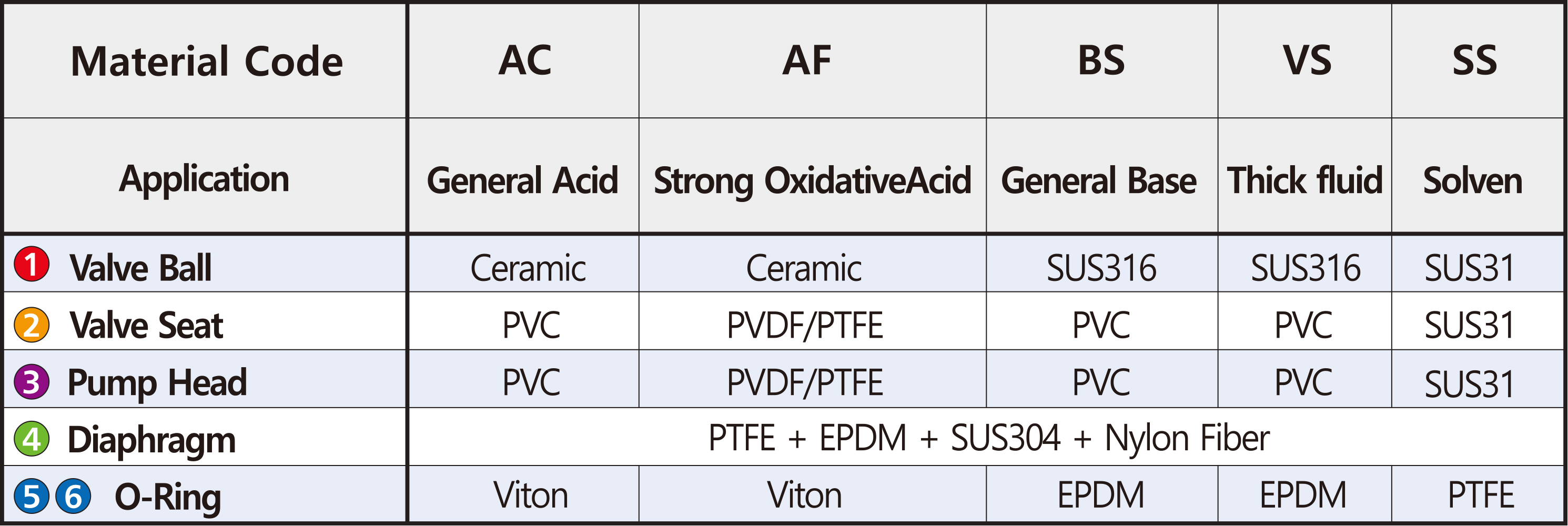

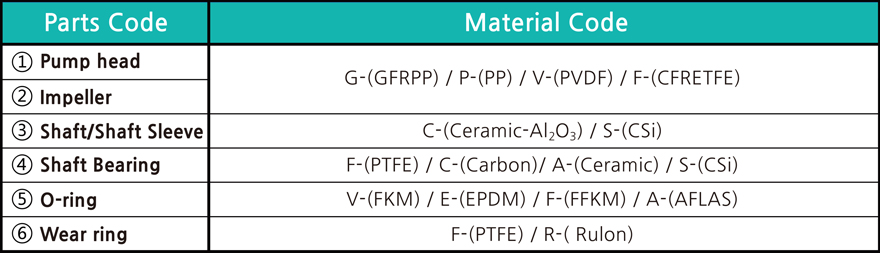

| D = Material Code | (Consult the Material Code List) |

| E = Joint Code | (H=Hose Type, U=UnionType, F=FlangeType) |

| F = Power Source Code | (U=Universal 100-240V/ø1,2=220V/ø1, 1=110V/01) |

| G = Special Code | (Null=Standard Product, A=Analog Function, D=Digital Function, B=Batch Function, T=Timer Function) |

Free Adjustment of Pumping Rate

The ratio between analog signal and pumping rate can be set as desired to meet the requirement of accurate dosing.

IP65 Protection Degree Certified

The special design and material of this pump, which makes IP65 degree of ingress protection. The pump can be mounted at outdoor.

Large-Scale LED Display

The oversized illuminated LED display provides excellent identification at dark places.

Electro-Magnetic Drive Design

Direct electro-magnetic drive mechanism. The power consumption is only 25Watts, which makes more energy saving.

Standard Equipped with Panel Protective Cover

A panel protective cover prevents from corrosive chemical, oil, dust, rain, which extend pump’s life.

| PVC | : Polyvinyl chloride |

| SUS304/316 | : Stainles Steel 304, 316 |

| Viton | : Fluoro Rubber(FKM) |

| EPDM | : Ethylene Propylene Rubber |

| PVDF | : Polyvinylidene fluoride |

| Ceramic | : Al2O3 |

| PTFE | : Polytetrafluoro Ethylene |

Precise Flow Rate Control

The precise stroke adjust mechanism ensure accurate control of flow rate.

Extra-thick Pump Head Design

The pump head is made of 34mm thickness of solid material to eliminate cracking problem.

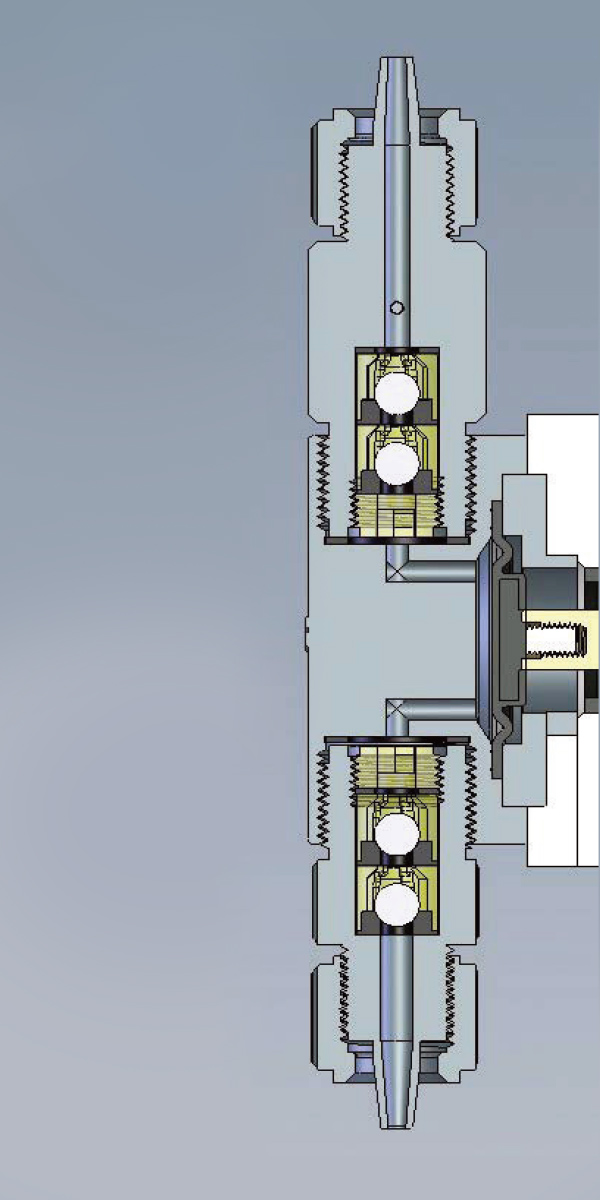

Double Check Valve Design

The inlet and outlet ports are equipped with double check valves. The flow rate precision is below ±2%.

Standard Equipped With Manual Exhaust Valve

Manual exhaust valve for releasing gas existed in the pump head, which keeps stable flow rate.

Swiveling Pump Base Design

Swiveling pump base increases convenience in installation.

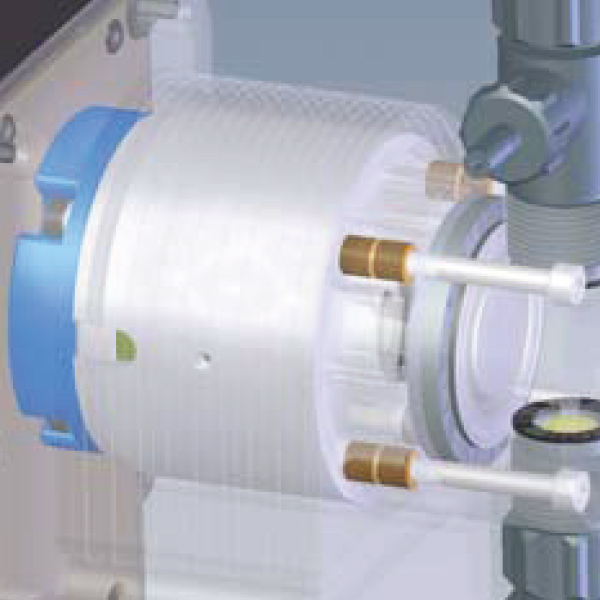

When there are requirements such as transfer/distribution/filtration/mixing of various chemicals, conventional pumps may be difficult to apply due to constraints on structure and In this case, a pump that is resistant to acid and alkali but does not leak is essential. Due to the magnet type design, the MDCP series pump is leak-free and corrosion-resistant. MDCP series pumps are produced and sold in Taiwan in cooperation with Japan’s headquarters, so their performance and quality are exactly the same as Japanese products.

FEATURES

- It has the same technology and quality as a large Japanese company, and has obtained certification from the Japanese headquarters.

- Complies with European CE electrical safety standards and quality control follows ISO 9001 quality standards.

- Various power/voltage/material specifications are available.

- Hose or pipe piping is possible, so it can be installed at various sites.

- Use stainless steel bolts (SUS304) on the outside.

- It can be installed and used outdoors with a high protection rating of IP54/64.

- Despite being small and lightweight, you can get a lot of flow and head with high transmission efficiency.

- Important components such as bearings, coils, and induction materials are excellent in power saving and durability by using products from large Japanese companies.

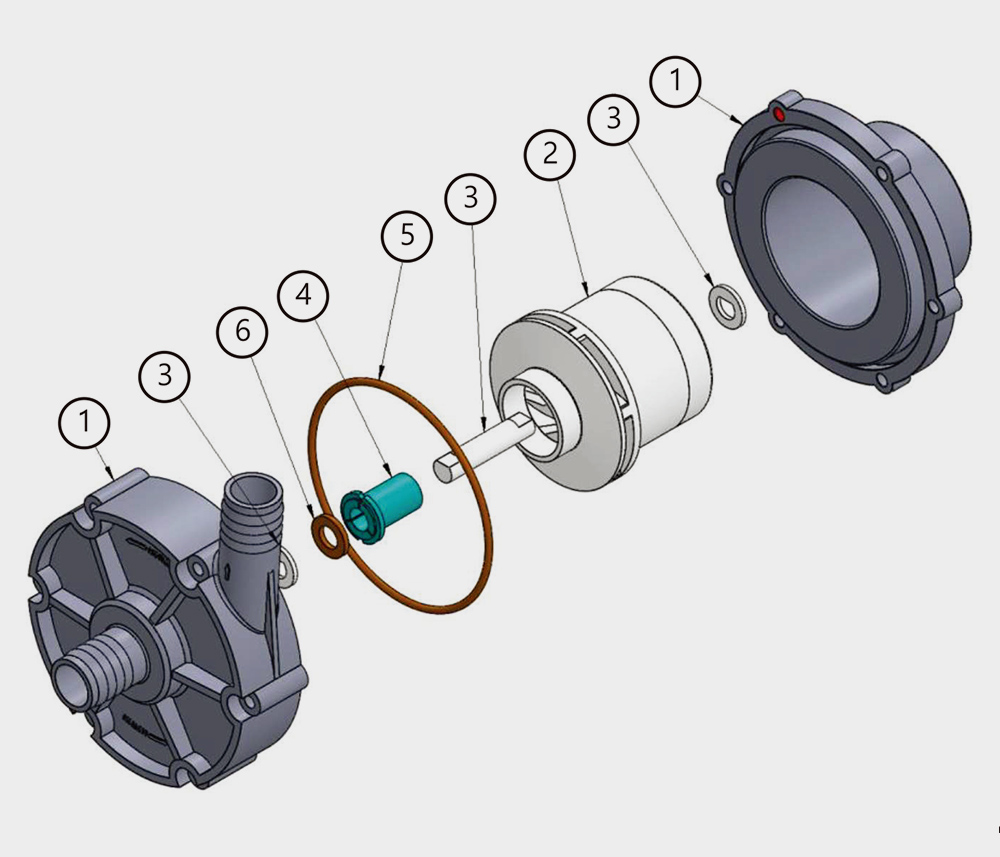

- The easy-to-decompose head-end design makes it easy to replace and repair abrasion parts.

- The magnet type design completely separates the fluid area and the motor drive area, so there is no leakage problem even in long-term use.

| A = Series Code | (Pump Series) |

| B = Output Power | (25=25W, 60=60W, 100=100W, 160=160W, 250=250W) |

| C = Power Code | (10=100V, 11=110V, 20=200V, 22=220V, 23=230-240V, 8=380V) |

| D = Phase of Motor | (1=ø1 단상전원, 3=ø3 삼상전원) |

| E = Joint Code | (H=Hose Type, U=Union, F=Flange) |

| F = Material Code | (영문5자로 구성, 설명은 아래 참조) |

| GFRPP | : Glass Fiber Reinforce Polypropylene |

| PP | : Polypropylene |

| PVDF | : Polyvinylidene Fluoride |

| PTFE | : Polytetrafluoro Ethylene |

| CFRETFE | : Carbon Fiber Reinforce ETFE |

| Ceramic-Al | : Ceramic-Al O |

| Ceramic-Si | : Ceramic-SiC |

| FKM | : Fluoro Rubber(Viton) |

| EPDM | : Ethylene Propylene Rubber |

| FFKM | : Perfluoro-elastomers Rubber |

| AFLAS | : FEPM |