DIRECTFLO® PUMPS

SAMOA

ADVANTAGES OF AIR OPERATED DOUBLE DIAPHRAGM PUMPS

- Dry-running capacity and dry self-priming.

- Can pump clean fluids or fluids with suspended solids.

- Best pump for abrasive, corrosive and shear sensitive fluids.

- Air driven pump, no electricity required, no electrical hazard.

- On-demand operation. Pump stops when fluid outlet closes

and automatically starts when the fluid outlet opens. - Adjustable flow and head pressure with only an air

pressure regulator. - No dynamic mechanical seals or packings.

ADDITIONAL Directflo® PUMPS ADVANTAGES:

INNOVATIVE DESING

- One piece fluid section guarantees no leakage.

- Fast and easy maintenance

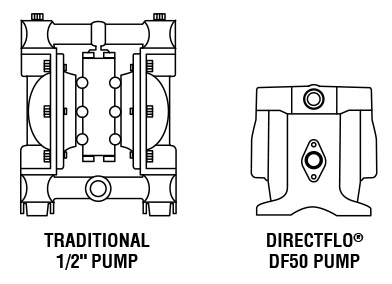

- No manifolds, very compact design.

PROVEN SUPERIOR PERFORMANCE

- Superior dry suction.

- Non icing, no stalling.

- Superior start-up reliability.

- Tolerates dry, damp, dirty and oily air.

- Gentle pumping, reduced pulsations and vibration.

INCREASED DURABILITY

- First quality materials.

- Long diaphragm life.

- Short diaphragm stroke.

MORE EFFICIENT PUMP

- Reduced air consumption.

- Reduced internal pressure drop.

Directflo® pumps are more compact allowing easy and economical installation in applications with:

- OEMs

- Hard to access places

- Congested areas with many pipes and other equipment. While producing equal to higher flow rates with reduced air consumption.

REVOLUTIONARY DIRECTFLO® TECHNOLOGY

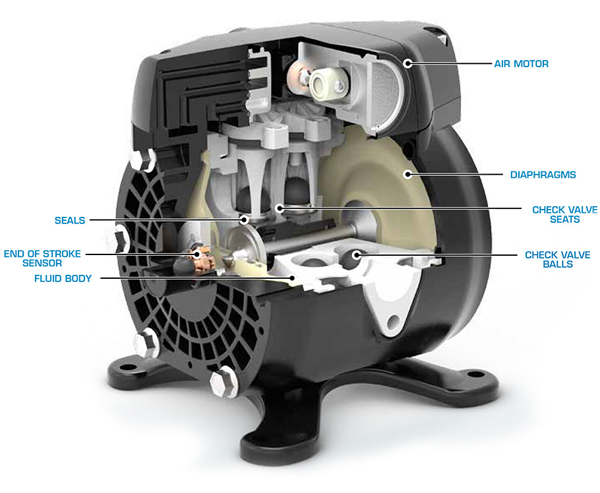

Directflo® pumps are based in an “inside-out” technology: the fluid is pumped through the centre of the pump while the compressed air acts on the external face of the diaphragms.

EXTREMELY FAST CHANGEOVER FRICTIONLESS PIVOT VALVE DESIGN

Very reliable and fast action air valve that reduces air consumption and minimizes pulsation.

SHORT STROKE DIAPHRAGMS GREATLY EXTENDS LIFE

CONSTRUCTION MATERIALS

ALUMINIUM

- Versatile material with good overall properties. Ideal for general purpose applications.

- Used in metal pumps for fluid bodies, air motors housings and valve seats in DP pumps.

- Not for use with halogenated hydrocarbons.

AISI 316 STAINLESS STEEL

- High corrosion resistance, mostly used in the chemical industry. High tensile resistance.

- Used in metal pumps for fluid bodies, valve seats and valve balls.

POLYPROPYLENE

- General purpose material. Good with water-soluble acids and caustics.

- Used in plastic pumps for fluid bodies, air motor housings and valve seats (DC and DP pumps).

- Also available as conductive Polypropylene (black colour) for groundable pumps (ATEX).

ACETAL

- Material with good mechanical properties. Compatible with most solvents.

- Used for valve balls and for valve seats in DC and DP pumps.

- Also available as conductive Acetal in fluid bodies for groundable pumps (ATEX).

PVDF

- A fluoroplastic, durable and with excellent chemical resistance.

- High tensile strength and impact resistance. Excellent temperature resistance.

- Used in plastic pumps for fluid bodies and valve seats.

PTFE (Teflon®)

- Excellent chemical resistance and good resistance to high temperatures.

- Used in diaphragms and valve balls.

UP: PIVOT UNIVERSAL PUMP

The new SAMOA Pivot Universal Pump (UP) combines a Universal design with a unique frictionless Pivot-Shaft Air Valve to provide maximum performance and energy efficiency, which exceeds performance expectations.

ADVANTAGES OF AODD PUMPS

- Pump can run dry with no damage

- Dry self-priming.

- Can pump fluids with suspended solids.

- Best pump for abrasive, corrosive and shear sensitive fluids.

- Air driven pump, no electricity required, no electrical hazard.

- Can be submerged completely with no performance or safety issues.

- On-demand operation. Pump stops when fluid outlet closes and automatically starts when the fluid outlet opens.

- Fluid flow and pressure are fully adjustable with only an air pressure regulator.

- No dynamic mechanical seals or packings.

ADDITIONALLY, UP SERIES PUMPS OFFER:

- HIGHER EFFICIENCY: Maximum fluid flow with reduced air consumption, versus competitive pumps.

- INCREASED RELIABILITY: No stall, no icing, and reliable start-up even with the lowest air pressure.

- MINIMAL VIBRATION AND PULSATION: Due to the fast action frictionless Pivot-Shaft Air Valve.

- BOLTED CONSTRUCTION: Provides improved sealing to eliminate pump leaks. Same size bolts for ease of maintenance.

- EASIER SERVICING: Components designed for a simpler and easier maintenance, with reduced number of parts.

- UNIVERSAL PUMP: Matches relative dimension of main competitive brands. Direct replacement for existing installed pumps.

- SUPERB ABRASION RESISTANCE: Optimized fluid paths and manifolds reduce fluid speed and minimize wear caused by abrasion

- SILENT OPERATION: UP pumps air valve produces less noise than competition pumps.

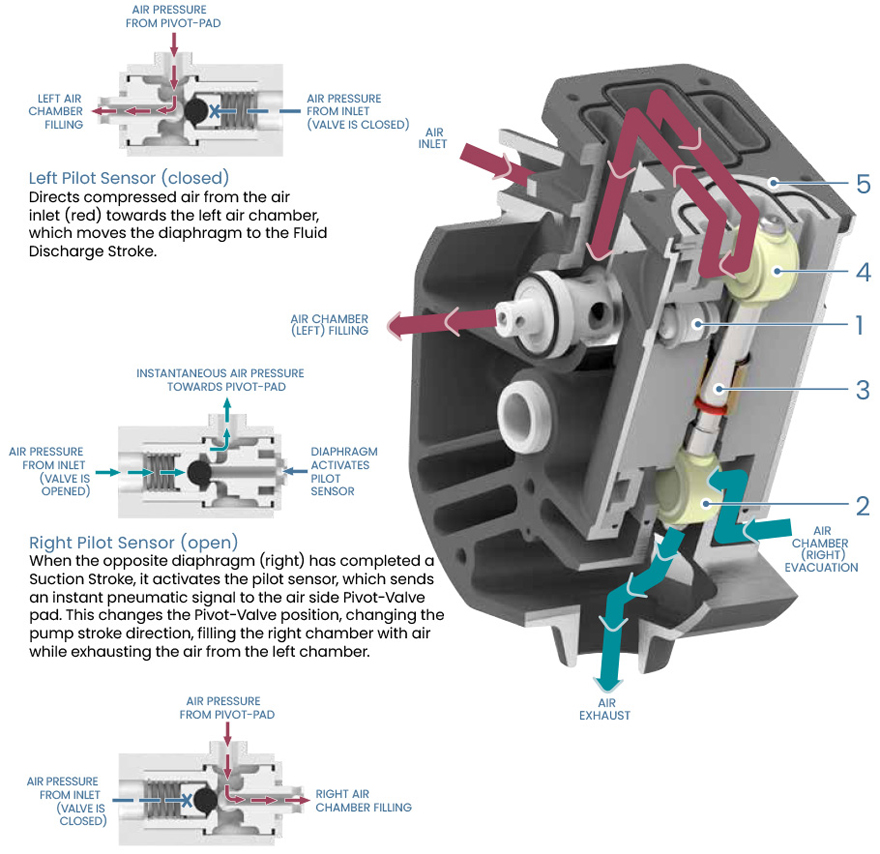

AIR DISTRIBUTION SYSTEM

SAMOA Pivot Series Universal Pump (UP) combines the innovative concept of a superior Air Distribution System (Central Body, Air Covers, Air Valve and Pilot Sensors) with an enhanced Universal Air Operated Double Diaphragm Pump design.

The exclusive Air Distribution System (ADS) incorporates an innovative Pivot-Shaft together with the “Smooth-Start-Shifter”(3S) actuator (patented). It provides reliable operation, even with very reduced air pressure and / or reduced air flow.

Additionally, the ADS design prevents freezing and delivers higher and smoother flow with reduced air consumption when compared to competitive AODD Pumps. Thanks to its modular concept, SAMOA ADS is very simple to clean and to maintain.

RELIABILITY, EFFICIENCY AND SIMPLICITY