Main application sectors

RUBY

CHEMICAL INDUSTRY

SHIPPING

GALVANIC AND

ELECTRONIC INDUSTRY

GRAPHIC INDUSTRY

PAINT INDUSTRY

PRODUCTION AND

STORAGE OF BIODIESEL

AUTOMOTIVE

PACKING, GLUE, PAPER

AND PAPER MILLS

CERAMIC,

STONE, MARBLE, GLASS

AND MINING INDUSTRY

WATER AND SLUDGE

TREATMENT

TEXTILE AND

LEATHER INDUSTRY

OIL & GAS

METAL PROCESSING

INDUSTRY

MECHANICAL AND

METALLURGIC INDUSTRY

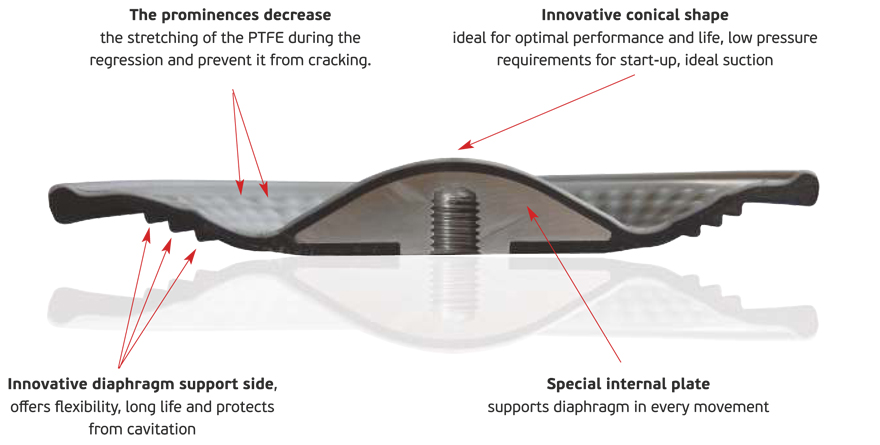

Ruby Diaphragms

Introducing the Advanced Composite Diaphragms of Ruby pumps

Diaphragms play a crucial role in the operation of a diaphragm pump. No matter what the pumping liquid is, from water to aggressive acids, diaphragms must meet the needs of very specific handling characteristics as they relate to product compatibility.

Diaphragms of Ruby pumps are constructed of high-quality materials and their design, enables them to produce reliable and optimal performance. Available in a full range of options, PTFE, PTFE-A, NBR, EPDM, VITON, they meet the specific needs of every pumping application.

- Excellent, extended service life

- Greater performance

- Higher displacement per cycle

- Easy to install and maintain

- Eliminated leak paths due to absence of central hole

- They can be installed and removed without the use of tools

- Our diaphragms last longer and are considerably stronger than other diaphragms.

- They can be used with most chemicals and are ideal for a wide range of pumping tasks.

- Longer diaphragm life in more abrasive applications that still require PTFE

Advanced Composite Diaphragms Offer:

New Air Valve Design

Designed and made using the most innovative technology, the Air Valve is the “heart” of the Ruby pump.

It functions without the need for lubricants or oils, hence:

- Eliminates the risk of seizing due to lubrication issues

- Protects the environment

- Saves money spent for lubrication

The innovative Air Valve of Ruby pumps also provides:

- Great saving energy due to fully managed airflow

- Low-maintenance

- Non- Internal freeze

- Non-dead-Centre asymmetric operation

- Long service life

- Low cost of spare parts

- Easy installation

- Reliability

- Does not contain metal parts (excluding shaft)

ATEX Certificate

Both plastic and metallic conductive series of Ruby Air Diaphragm Pumps comply with the demands of EU Directive 2014/34/EU and are certified by ATEX II 2/2 G/D so they can operate safely in potentially explosive atmospheres where flammable gases, mists or dust particles may be present.

Plastic Conductive and AISI 316 pumps are also certified by ATEX I M2 for use in underground parts of mines.

ATEX Certificate has been issued by the European notified body TÜV NORD. Certificate number: C 004-2

Ruby Pumps composition codes:

example: model Ruby 126P-P-TPT-F

Pump Model Ruby 126, PP Pump Body, PP Center Section, PTFE Diaphragms, PP Ball Seats, PTFE Ball Valve, VITON O-ring

| R 126 | P | P | T | P | T | F | – |

| Pump Model | Pump Body | Center Section | Diaphragms | Ball Seats | Ball Valve | O-ring | Other Options |

| MINI 005 Ruby 008 Ruby 010 Ruby 115 Ruby 120 Ruby 025 Ruby 125 Ruby 126 Ruby 140 Ruby 141 Ruby 150 Ruby 151 Ruby 081 Ruby 180 |

P : PP V : PVDF+CF A : Aluminum S : Stainless Steel 316 PC : PP+CF |

P : PP A : Aluminum PC : PP+CF |

N : NBR Conductive E : EPDM Conductive F : VITON Conductive T : PTFE+back up (EPDM Conductive) Z : PTFE A+back up (EPDM Conductive) ST : PTFE+back up (SANTOPRENE) HY : PTFE+ back up (HYTREL) NT : PTFE+Back up (NBR) |

V : PVDF S : AISI 316 A : Aluminum P : PP N: NBR E : EPDM O : POM-C |

T : PTFE S : AISI 316 N : NBR E : EPDM |

T : PTFE F : VITON E : EPDM N: NBR |

F : Flange PN10/ANSI 150 D : Twin Manifod |